Kurukshetra February 2024

Chapter 1- Shaping Sustainable Food Systems with Storage Infrastructure

- Agriculture is the mainstay of the Indian economy, which has witnessed a magnificent transition from being a food deficit to a food surplus and is now an agriculture produce exporter to the world.

- India holds the second-largest agricultural land in the world, with over 200 countries in its export basket (Ministry of Commerce & Industry, 2023).

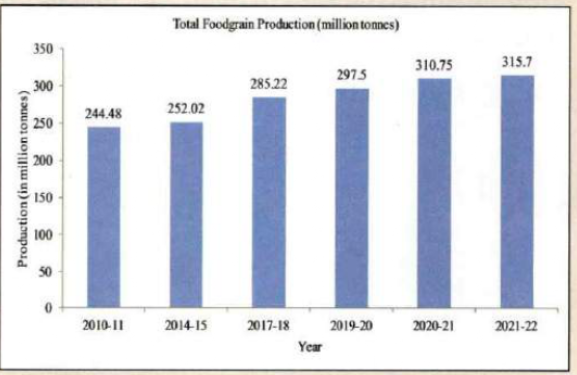

- Food production in India has increased significantly since the last decade, from 244 million tonnes during 2010-11 to 310 million tonnes during 2021-22.

- India is on the path of becoming a developed nation-Viksit Bharat by 2047- marking the centenary year of India’s Independence.

- The vision of a developed nation by 2047 encompasses economic growth, social progress, environmental sustainability, and good governance.

- As per the FAO’s State of Food and Agriculture (2019) report, around 14 percent of the world's food (valued at $400 billion per year) is lost after it is harvested and before it reaches the shops.

- UNEP’s Food Waste Index Report (2021) showed that a further 17 percent of the food ends up being wasted in retail and by consumers, particularly in households (United Nations Environment Programme, 2021).

- Food that is lost and wasted accounts for 38 percent of total energy usage in the global food system.

- As per the study commissioned by the Ministry of Food Processing Industries, the economic value of quantitative losses of 45 major crops/commodities was found to be in the tune of Rs. 92,651 crore.

- Enhancing sustainable and world-class storage infrastructure are inevitable to boost growth in agriculture and allied sectors and achieving the targets of UN-Sustainable Development Goals.

- During 2022-23, total food grains production in the country is estimated to a record high of 329.68 million tonnes, which is higher by about 14.1 million tonnes than the production of food grains of 315.62 million tonnes achieved during 2021-22.

- India accumulates a huge stock of staple food for specific purpose of supporting the poor and needy during urgent times.

- Pradhan Mantri Garib Kalyan Anna Yojana (PMGKAY) is the World’s biggest social welfare scheme aimed at ensuring national food and nutrition security and empowerment of weaker sections of the society.

- It envisions providing free food grains to about 81.35 crore beneficiaries for a period of five years with effect from 1 January 2024.

- The enhanced storage infrastructure will support meeting the food-demand, supply, and access to the nationals across the country.

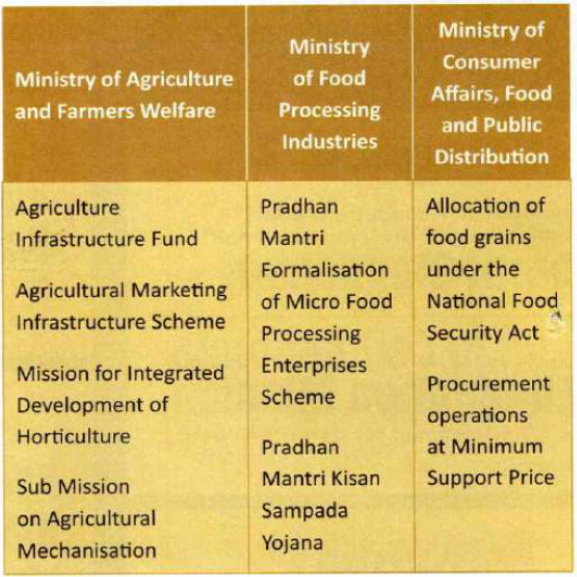

- Various initiatives have been taken by the Government to encourage storage infrastructure and strengthen food systems under the

- Agriculture Infrastructure Fund (AIF),

- Agricultural Marketing Infrastructure Scheme (AMI),

- Sub-Mission on Agricultural Mechanization (SMAM),

- Pradhan Mantri Formalization of Micro Food Processing Enterprises Scheme (PMFME),

- Pradhan Mantri Kisan Sampada Yojana (PMKSY), and

- Mission for Integrated Development of Horticulture (MIDH).

Sustainable Food Systems

- The sustainable food system delivers food security and nutrition for all in such a way that the economic, social and environmental bases to generate food security and nutrition for future generations are not compromised.

- Here, storage infrastructure plays a significant role in adding resilience to the food system and will positively impact food security and food availability.

- The use of scientific storage methods can reduce these losses to as low as 1%-2%.

- At present, several structures ensure the safe storage of grains, ranging from small metal bins to tall grain elevators/silos.

- These storage structures are classified under different categories like traditional storage structures, improved storage structures, modern storage structures, and farm silos.

- Warehouses are scientific storage structures especially constructed for the protection of the quantity and quality of stored products.

- Also, advanced cold chain storage infrastructure capacity has been strengthened for perishable food commodities.

- The cold storage capacity of 8.38 lakh MT has been created under the Integrated Cold Chain and Value Addition Infrastructure scheme.

Estimations of Post-harvest Food Losses

- Studies indicated that the major post-harvest losses are reported in the allied sector, i.e, fisheries and eggs.

- Amongst the horticultural crops, the trend in losses is higher in fruits (between 6 - 16%) followed by vegetables (4-12%) than in plantations and spices (between 1-8%), respectively.

Government Initiatives

- The Food Corporation of India (FCI) is set up under the Food Corporation’s Act of 1964 and is the only government agency entrusted with the movements of food grains from procuring states to consuming states through a network of storage infrastructure, owned or hired by FCI in the whole of India.

- FCI augments its storage capacity through the following schemes:- Private Entrepreneurs Guarantee (PEG) Scheme, Central Sector Scheme (CSS), Construction of Silo's under Public Private Partnership (PPP) mode, Hiring of godown from Central Warehousing Corporation (CWC)/ State Warehousing Corporations (SWCs)/State Agencies, Hiring of godown through Private Warehousing Scheme (PWS).

- As on 01.07.2023, the Food Corporation of India has a network of 1923 warehouses (Owned/Hired) with a capacity of 371.93 LMT for storage of Central Pool food grains.

- The total food grain production in India is about 311 MMT and total Storage Capacity in India is only 145 MMT, i.e., there is a shortage of 166 MMT of Storage.

- To address the shortage of food grain storage capacity in the country, the Government last year approved the 'World’s Largest Grain Storage Plan in Cooperative Sector', which have been rolled out as a Pilot Project in different states/UTs of the country.

- It entails creation of various agri infrastructure at the Primary Agricultural Credit Societies (PACS) level, including setting up decentralised godowns, custom hiring centers, processing units, Fair Price Shops, etc. through convergence of various existing schemes of the Government of India (Gol) under different Ministries.

- These Pilot projects are implemented by the National Cooperative Development Corporation (NCDC) with the support of NABARD, Food Corporation of India (FCI).

- Through schemes, PACS can avail of subsidies and interest subvention benefits for the construction of godowns/storage facilities and setting up of other agri-infrastructure.

- NABARD is also extending financial support to PACS by refinancing them at highly subsidized rates of around 1 per cent, after incorporating the benefits of 3% interest subvention under the AIF scheme for projects up to Rs. 2 Crore.

- There has been a recent push to increase the cold storage capacity available in India — with extensive tax breaks.

Achieving Sustainable Development Goals

- Food grain storage will directly support in achieving the targets made under the Sustainable Development Goal of zero hunger, which aims to end all forms of hunger and malnutrition and double the agricultural productivity and incomes of small-scale food producers.

- Also, indicators under target 12 i.e. sustainable consumption and production can be achieved through advancement in storage infrastructures in India.

Way Forward- The promotion of decentralized local storage system will reduce the wastage of food grains, strengthen food security, and prevent distress sales by farmers. The increased investment in modernization of warehousing, logistics, cold chain, food processing, and integrated value chain development can enable the goal of becoming a development nation and achieving the Sustainable Development Goals.

Chapter 2- Institutionalized Management of Food Security

- At present, the projected population of India is about 1.40 billion, which constitutes about 17.5% of the global headcount of 8 billion.

- The Government of India distributes free food grains under Pradhan Mantri Garib Kalyan Ann Yojana (PMGKAY) to about 81.35 crore people across the country.

- At the time FCI was established on 14 January 1965, India was a food-deficit nation that often imported food grains from other nations, particularly from United States of America (USA) under PL-480 agreements.

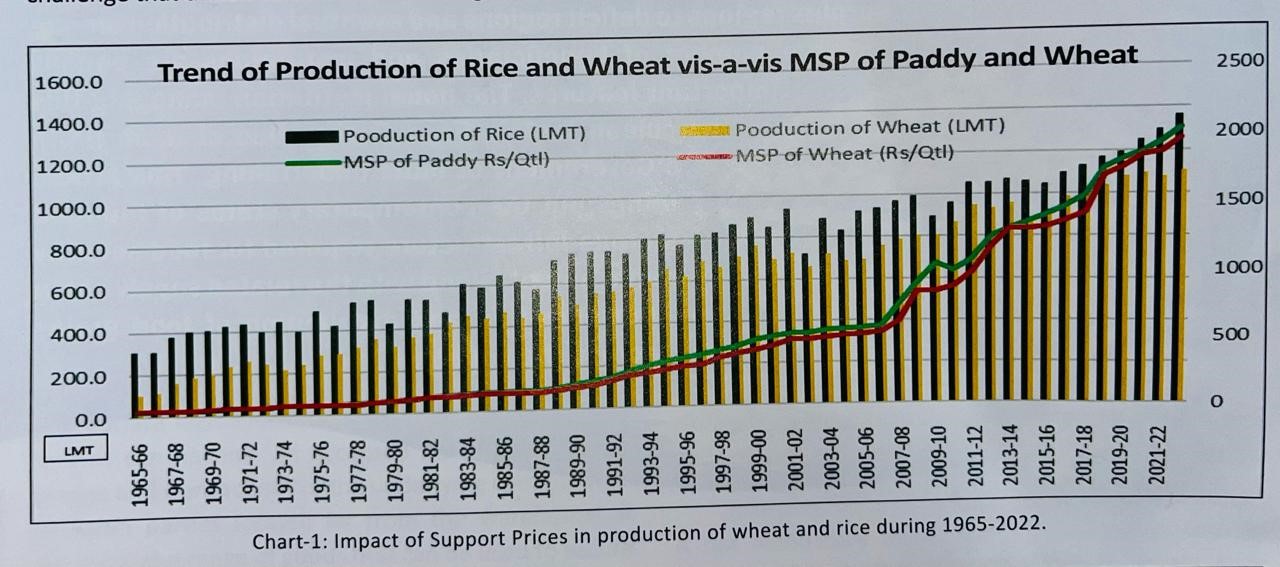

- During this era India launched ‘Green Revolution” to augment food production with the use of high yielding verities of seeds and deployment of technology in agriculture.

- MSP purchase by FCI and allied state government agencies, particularly wheat and paddy is known as central pool procurement and led to constant increase in production.

- The continued procurement from farmers encouraged them to produce more, due to which procurement share of the total production also start rising.

- FCI has been mandated to-

- To provide remunerative prices to the farmers,

- To provide food grains to vulnerable sections of the society at affordable prices,

- To maintain buffer stock reserves for exigencies, and

- To intervene in market for price stabilization.

- In order to achieve these mandates, FCI had to constantly enhance its operations, particularly transportation, and distribution of food grains.

Storage Operations for Food Grains in Central Pool

- For any agricultural produce and its value-added products, it is important that they are stored properly for preservation of their qualities, future usage, and consumption.

- Food grains like wheat and rice with low-moisture and low pH activity fall under the non-perishable category and can be stored for a longer duration of 1 to 4 years.

Preservation of Food Grains during Storage

- In order to maintain and preserve the quality of stored food grains in godowns and silos, FCI regularly conducts periodical inspections by trained professional staff.

- Food grains are inspected for classification, categorisation, disinfestation, and fitness for liquidation followingthe FIFO principle.

- Food grains are kept infestation-free by prophylactic treatment with malathion and deltamethrin and disinfected by curative treatment through fumigation with aluminum phosphide.

Storage Capacity in Central Pool

- By the end of 2023, FCl has 761.29 lakh MT storage space for safe storage of food grains at about 2000 locations.

- This storage capacity is about 125 times the storage capacity on 6.18 lakh MT at the time of its inception in 1965-66.

- While 363.69 lakh MT is with FCl, about 397.60 lakh MT is with state government agencies.

Transportation and Distribution of Food Grains

- Procured food grains from surplus states are transported to deficit states.

- Efficient transportation is pivotal in connecting surplus in-producing regions with deficit areas.

- FCl employs multimodal transportation approach, utilizing railways, roadways, and waterways.

- Typically, wheat is transported from Punjab, Haryana, and Madhya Pradesh to all other states, while rice is transported from Punjab, Haryana, Uttar Pradesh, Uttarakhand, Chhattisgarh, Odisha, Andhra Pradesh, Telangana, and Madhya Pradesh to all other states.

- The food grains transported in the deficit regions are also stored in local godowns to reach 5.45 lakh Fair Price Shops (FPSs) across the country through state government agencies.

Technology Integration and reduction in losses- The integration of digital system for inventory management like Depot-on-Line System (DoS), GPS-enabled Vehicle Tracking System (VLTS), linking of rice mills with individual Depots/ warehouses for delivery of rice, and allocation of space at individual warehouses for absolute transparency in the procurement process (WINGS) etc have improved the accuracy and efficiency of FCI’s process and also contributed to transparency and accountability throughout the supply chain.

Conclusion- Thus, FCI's food supply chain not only ensures food security to all the needy citizens in every nook and corner of the country but also make it the world’s largest food system. The efforts to modernise its operations and to take along all the stakeholders is a continuing process to improve its efficiency and effectiveness.

Chapter 3- Mega Food Storage Plan

- India is the second-largest producer of foodgrains in world, with an annual production of about 3,100 lakh tonne.

- However, currently the country has a foodgrain storage capacity of 145 million metric tonnes (MMT) against the total production of 311 MT- leaving a gap of 166 MMT.

- This means the existing storage infrastructure can only accommodate approximately 47 percent of the total produce.

- When compared to the USA and China, which process 65% and 23%, respectively, of their perishables, India is able to process a meagre 7%, which is quite negligible.

- The USA, Brazil, Russia, Argentina, Ukraine, France, and Canada have the capacity to store more food grains than they produce.

- Unfortunately, poor systems and techniques of handling, storage, and distribution result in postharvest losses of around 10-16 per cent for major cereal crops, 26 per cent in the case of wheat, and 34 per cent in the case of vegetables and fruits.

- Under the new plan, the Ministry of Cooperation has approved a network of integrated grain storage facilities through Primary Agricultural Credit Societies (PACS) across the country.

- There are more than 1,00,000 PACS spread across the country, with a huge member base of more than 13 crore farmers.

- This will be the world’s largest grain storage plan in the cooperative sector.

- The integrated modular PACS will have a custom hiring centre, procurement centres, primary processing units for cleaning and winnowing, a storage shed and container storage, and silos as well.

- It purports to enhance food grain storage capacity by 70 MMT in the cooperative sector.

- The plan entails the creation of various types of agri-infrastructures at the Primary Agricultural Credit Societies (PACS) level, including warehouses, custom hiring centres, processing units, fair price shops, etc. by leveraging the ‘Whole-of-Government approach’.

- The plan is being implemented by schemes of the different ministries shown in tabular form.

- An Inter-Ministerial Ministerial Committee (IMC) has also been constituted for the effective and seamless implementation of the scheme.

Why Mega Plan Needed?

- India, the most populous country in accounts for 18 per cent (1.4 billion) of population (7.9 billion).

- It contains only 1percent (160 million hectare) of the cultivable land (1,380 million hectare).

- India runs the world’s largest food programme under the National Food Security Act, 2013, that covers about 81 crore people.

- Therefore, to ensure food security of a billion plus population, a robust network of food grain storage facilities becomes essential

Implementing Agencies- The National Cooperative Development Corporation, with the support of NABARD, NABARD Consultancy Services, the Central Warehousing Corporation, the Food Corporation of India, etc., is implementing the pilot project in 24 PACS of 24 different States/UTs.

Why Implement

A number of benefits can be derived by augmentation of the Storage facilities, such as-

- reduce transportation costs for farmers, enabling them to maximise their profits.

- Farmers would have a choice to sell their produce depending on the market conditions.

- The modern silos will have the facility of computerised real-time monitoring systems.

- Strengthening food security will ensure a more stable and consistent supply of food grains across the country, thus reducing our dependence on imports.

- It will create numerous employment opportunities in rural areas.

- It will led to leverage the strength of cooperatives and transform them into successful business enterprises, aligning with the vision of ‘Sahakar se Samriddhi’.

- It seeks to empower PACS, which play a significant role in the agricultural and rural landscape.

Challenges Ahead

- Conflict with FPOs: FPOs are also involved in post-harvest handling of the produce that may come in conflict with the agriculture cooperatives.

- Agri-Cooperatives: Agriculture cooperatives have been given financial responsibilities and storage infrastructure implementation.

- Infrastructure Management and Maintenance: It is easy to create infrastructure, but managing and maintaining it is a bigger challenge.

- Food Quality Management: Often the poor-quality grains are distributed under Public Distribution System, due to low quality storage infrastructure with primitive technologies.

- Multiplicity of institutions with crosscutting objectives is likely to dilute their effectiveness.

- Policies formulated for small and marginal farmers often end up serving the interest of medium and large farmers.

Possible Solutions- The latest data shows that the value of food losses (agriculture, horticulture, milk, meat, and fish) turns out above Rs. 1,40,000 crore per year. Hence, find out practical solutions for removing hurdles is necessary.

- It would be much better if this scheme is implemented in Public-Private Partnership mode.

- Modernization of the existing storage infrastructure needs to be prioritised.

- Adequate storage facilities should be provided to horticultural crops.

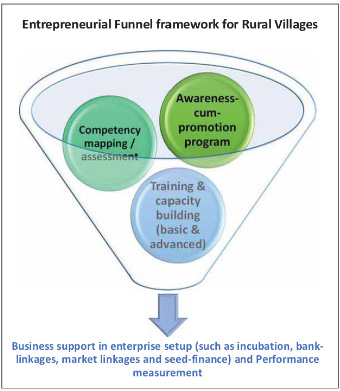

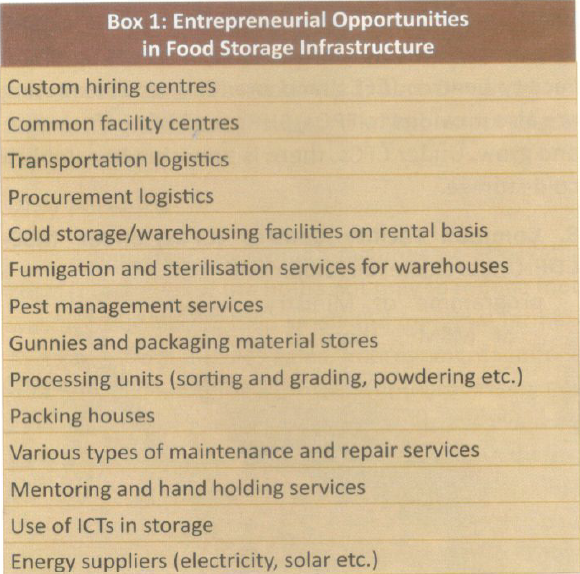

Chapter 4- Entrepreneurial Opportunities in Food Storage Infrastructure

- With a potential size of US$ 535 billion in 2025, India’s food processing sector provides ample opportunities for entrepreneurs as well as farmers.

- The Shanta Kumar Committee (2015) has recommended modernizing storage to ensure enhanced quality of food grains, negligible loss as compared to food grains storage in bag, efficient utilization of land, higher operational efficiency, and bring in private investment into the sector.

Entrepreneurial Possibilities in Food Storage Infrastructure

Agrifood supply chains involve:

-

- Production: Inputs such as seed, feed, and harvesting services and equipment;

- Processing: Activities such as washing, drying and freezing food;

- Aggregation and Distribution: Things such as marketing cooperatives, storage facilities, brokerage services, logistics management, and delivery trucks;

- Retailing: All those who sell or serve food to consumers, from restaurants, grocery stores and to schools, caterers, and fast-food outlets etc.

- Marketing: The efforts that goes into product promotion.

- Capital: Finance, natural capital (i.e. land, water and other ecological resources), human capital, and social capital.

- The food industry faces huge challenges such as food supply, food security or food waste that might offer interesting opportunities for aspiring entrepreneurs developing innovative solutions to these pressing issues.

Schemes and Programmes- Under Pradhan Mantri Kisan Sampada Yojana (PMKSY), establishment of mega food parks, massive scale cold chain structures, the development, and growth of food processing and preservation capacities, agro-processing clusters, etc. are supported.

Few of the important schemes are as discussed below-

- Mega Food Parks: It aims to link agricultural production to markets by using a cluster approach, implemented by an SPV.

- Cold chain, Value Addition and Preservation- It aims to provide integrated cold chain and preservation infrastructure facilities along the entire supply chain of food processing.

- Creation of Food Processing and Preservation Capacities: It aims to create and modernize processing and preservation capacities by increasing the level of processing and value addition, leading to a reduction in wastage.

- Creation of Backward and Forward Linkages: It aims to provide effective and seamless backward and forward integration in the processed food industry. Financial assistance is provided for setting up primary processing centers, collection centers, and modern retail outlets.

- Food Safety and Quality Assurance Infrastructure: It aims to make India’s food and agro-processing sector have a competitive edge in the market by creating infrastructure for safety and quality assurance services.

- Agro Processing Cluster: It aims at cluster approach-based development of modern infrastructure and common facilities to encourage a group of entrepreneurs to set up food processing units.

- PM Formalisation of Micro Food Processing Enterprises (PMFME): It is implemented by the Ministry of Food Processing Industry (MoFPI). It aims at providing financial, technical, and business support for the upgradation of existing micro food processing enterprises.

- Common Facility Centres (CFCs) under MSE-CDP- Export Promotion Facilities for FPO such as for processing, storage (cold chains), Pack Houses, testing, and packaging.

- Mission for Integrated Development of Horticulture (MIDH): Under this, apart from other things, financial assistance is provided for setting up of Pre-cooling Unit, Cold Room, Pack Houses, Integrated Pack House, Preservation unit, Reefer Transport, Ripening Chamber, etc.

Way Forward- Adequate food storage facilities at affordable costs is the need of the hours not only to reduce food wastage but also to help small and marginal farmers to escape from distress sales.

Chapter 5- Making India the Food Basket of the World

- Out of 8 billion people on this planet, 828 million are going hungry every day.

- Currently, India is the second-biggest producer of wheat and rice, the two staples.

- It has cultivable land, all the seasons for production of all varieties of fruits and vegetables, and an agribusiness system that works.

- India exports wheat to about 70 countries and rice to about 150.

Some of the strengths outlined below underline India’s intent to be the world’s food supplier:

Millets

- India could help mitigate the world food crisis by offering millets.

- India is the largest producer of millets in the world.

- India’s two varieties of millets, namely pearl millet (bajra) and sorghum (jowar), will together contribute approximately 19 percent in world production in 2020.

- The major millet producing states in India are Rajasthan, Karnataka, Maharashtra, Uttar Pradesh, Haryana, Gujarat, Madhya Pradesh, Tamil Nadu, Andhra Pradesh, and Uttarakhand.

- Terming millets as part of India's 'Super Food Bucket', we have given it (millets) the identity of Shree Anna.

- India spearheaded the United Nations General Assembly (UNGA) resolution for declaring the year 2023 as the International Year of Millets.

- High-yielding varieties, including bio-fortified millets, have been introduced to increase production, and the Government has recognised the health benefits of millets by including them in the POSHAN Mission and designating them as nutri-cereals.

Food Processing Industry

- It has an important role to play while India seeks to create a food basket for the world by linking the farmers to the final consumers in domestic as well as international markets.

- In the next ten years, food production is expected to double.

- These products, if processed and marketed smartly, can make India a leading food supplier in the world.

- The sector’s size is estimated to be around US $ 322 billion, and it is expected to reach US $ 543 billion by 2025, growing at a CAGR of 14.6%.

Food Supply Chain

- India is one of the country to become the food and grocery market in the world, a large consumer of food products, and has a huge opportunity to become a leading global food supplier through the right marketing strategies and an agile, adaptive, and efficient supply chain.

- The food supply chain is complex, with perishable goods and numerous small stakeholders.

- Data integration, financial flow management, supply-demand matching, collaborative forecasting, information sharing, and goods movement synchronization through efficient transport scheduling, are very well practiced in high technology industries with immense benefits.

Food Packaging

- Packaging is also emerging as a key ingredient as the country marches towards creating a food basket for the world.

- Packages have become the competitive tool to reach the consumer, and the task assumes increasing responsibility with more and more competitive and substitute products being introduced.

Standards

- It is a powerful tool for improving supply chain efficiency.

- There are two kinds of standards in the food supply chain. The first one is the food standard, which concerns itself with the content, the manufacturing process, the packaging, etc.

- The second standard concerns logistics and IT systems like standardization of cartons, pallets, and IT software so that seamless transfer of goods and information is possible.

- The increase in world food trade and the advent of the Sanitary and Phytosanitary (SPS) Agreement under the World Trade Organization (WTO) have led to increasing recognition and adoption of food safety measures.

Conclusion- India can become the largest food supplier in the world. It has cultivable land, all the seasons for production of all varieties of fruits and vegetables, and an agribusiness system. Investments in cold chain infrastructure, applied research in post-harvest technologies, the installation of food processing plants in various sectors, and the development of the food retailing sector are mandatory for achieving gains in this sector.

Chapter 6- ODOP Providing Framework for Value chain Development

- ‘One District One Product’ (ODOP) initiative has been taken by Government of India to foster the inclusive development, to harness the export potential of each districts and helping in integrated development of local economy.

- It is an initiative under ‘Pradhan Mantri Formalisation of Micro Food Processing Enterprises (PMFME) Scheme.

The major objectives of the PMFME scheme through ODOP are:

- improved access to financial assistance to micro food processing entrepreneurs for technological upgradation;

- capacity building through skill training, enhanced technical knowledge, and hand holding & anchoring services;

- support to Farmer Producer Organizations (FPOs), Self-Help Groups (SHGs) and Cooperatives;

- enabling the existing informal entities into formal registration as ‘agri-based business enterprises.

- Under this ODOP scheme, the Government of India approved 137 unique products in 713 districts of 35 States and UTs.

- Under the branding and marketing component, the FPOs, SHGs, Cooperatives as ‘Special Purpose Vehicles (SPV)" of ODOP-based micro food processing enterprises have been getting support for market study and product standardization, packaging material, quality control and food safety compliance for consumer retail sales, warehousing and storage rentals, and marketing of agri-products.

- The ODOP intervention has enabled and of onboarding of sellers of identified products on e-commerce platforms, which in turn, enhance visibility for the small businesses and farmers from rural areas.

- Under PMFME Scheme, the top 5 performing states are Maharashtra, Bihar, Tamil Nadu, Uttar Pradesh, and Telangana.

- Within the scheme, individual micro-enterprises will get the assistance in the form of capital subsidy with credit-linkage at 35% of the eligible project cost, up to a maximum of Rs.10 lakhs per unit.

- Additionally, clusters and groups like FPOs, SHGs, Producers Cooperative, will receive credit-linked grant at 35% for capital investment.

- The ODOP has facilitated in attaining balanced regional development across all the districts and will enable socio-economic development across India.

Value Chain Development, Infrastructure and Marketing Support-

- Common Infrastructure- It has provisions for usage of common infrastructure facilities at rural area for all the FPOs, SHGs, Cooperatives, while the private enterprises use the facilities on hiring basis, thus making the best use of existing capacity.

- Development of Clusters: There can be more than one cluster for one product in one district or it can be extended beyond two or more districts, particularly for value chain development and alignment of relevant support infrastructure, depending upon the nature of products and perishable goods. The scheme also supports strengthening of forward and backward linkages to provide common facilities, skilling/training, incubation centres, research and development, marketing, and branding.

- Value Addition: The cluster-based approach adopted by various States/UTs in India have played an enabling role regarding storage for agri-based products, preventing the wastages, facilitating processing and most importantly ensuring effective marketing ecosystem for the various products under ODOP.

- Branding and Marketing: Through this scheme a common brand, common packaging and common standard is highly critical.

- Institutional Architecture- With committees at district, state, and national level, the project envisages proper planning, effective execution, and close monitoring through robust institutional architecture.

ODOP Prospects and Benefits

The ODOP scheme has variety of benefits such as-

- Local and community development like in-situ employment, empowering rural women and youth.

- Promoting and preserving the local best practices/ micro-enterprises.

- Skilling, upskilling. reskilling and training of local talent.

- Local to global approach.

Way Forward

The success of ‘Democracy and Swaraj’ depends upon ‘how we plan for the unplanned and how we reach the unreached, how we get the best out of everyone, every district and every sector’.

The ODOP intervention has received a lot of accolades and awards for its ‘bottom-up approach’ andits significant contribution to integrated development of India.

In summary, India will emerge as a stronger economy with well-founded public policy support, enhanced awareness and infrastructure, improved institutional architecture along with cluster development, value addition, systematic marketing and branding for identified products, etc., through effective implementation of ODOP and its measurable outcomes, thereby achieving the goal of ‘Atamanirbhar Bharat’.

UPSC Mains Practice Questions

Q1. What are the main bottlenecks in upstream and downstream process of marketing of agricultural products in India?

Q2. The real challenge to India’s food security is poor grain management rather than a shortage of grain production. Comment. (250 words

QUICK LINKS